Defying global crises

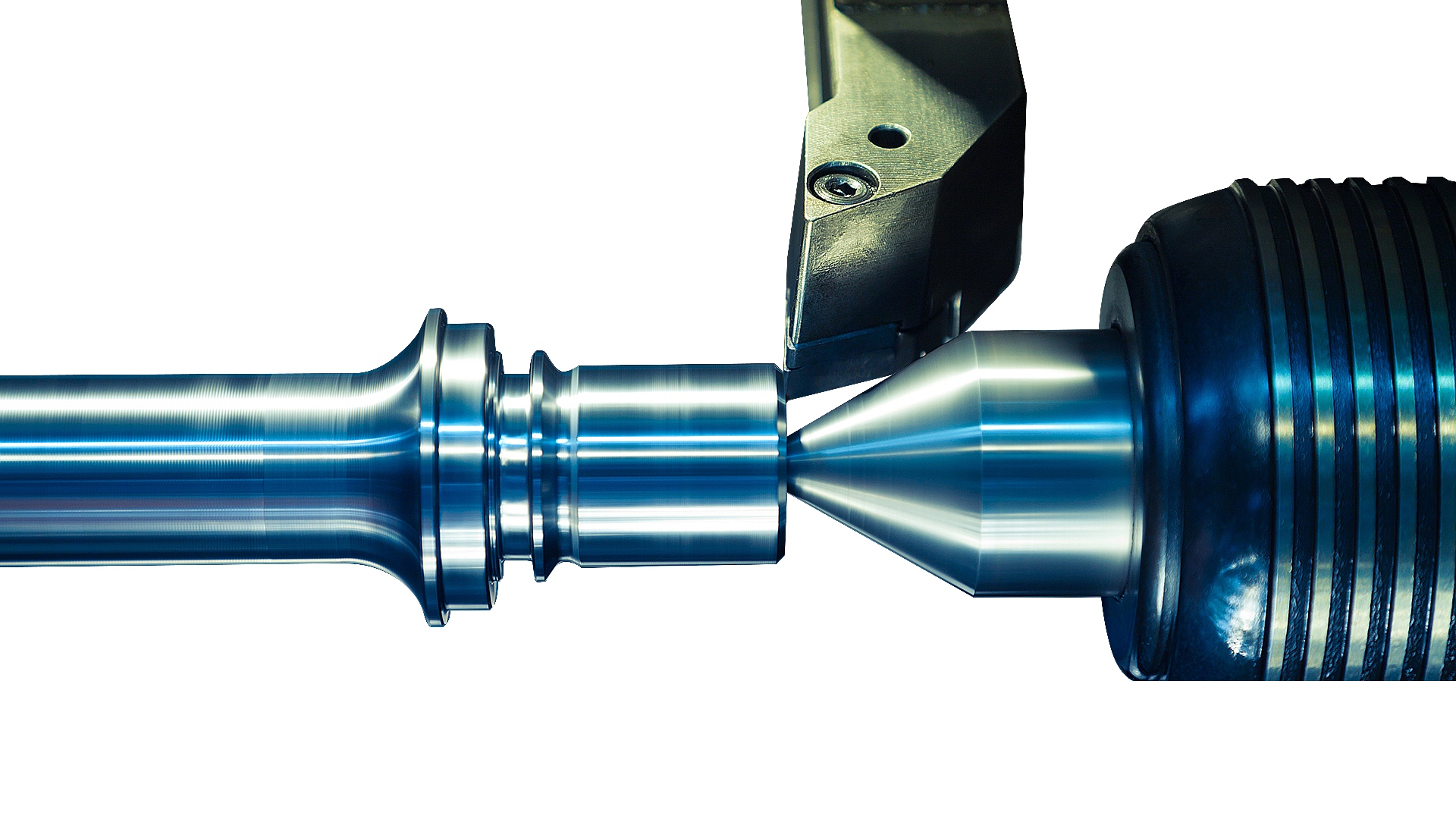

Repeated supply chain disruptions, rising producer prices and volatile markets have become a new normal in recent years. Industrials, which are dependent on intermediate products, raw material prices and global value chains, are particularly affected by this. In addition, high price pressure is arising in many sectors due to cheaper production costs of foreign suppliers – the intensity of competition is increasing. What is more, the crises can hardly be predicted or planned for. Consequently, uncertainty in the German economy is high.

Our proposition: „We advise companies on how to focus on realistic scenarios in the face of high uncertainty and how to deal with raw material shortages, logistics bottlenecks and price increases – for example, by proactively adjusting contracts on the supplier and customer side. In this way, negative effects can be cushioned and sustainable competitiveness ensured.“

We advise companies on how to focus on realistic scenarios in the face of high uncertainty and how to deal with raw material shortages, logistics bottlenecks and price increases - for example, by proactively adjusting contracts on the supplier and customer side. In this way, negative effects can be cushioned and sustainable competitiveness secured.

Ralf Winzer

Senior Partner & Member of the Board